Recent research carried out by British Columbia University has confirmed the effectiveness of copper coatings for the prevention of infections that patients can contract in hospitals, clinics and nursing homes during medical visits.

The capacity of copper and its alloys has been known for some time (Cu > 60%), such as bronze, Brass, cupronickel is Cu-Zn-Ni, to neutralize various dangerous bacteria, mushrooms, virus, Escherichia coli from Helicobacter pylori and tuberculosis.

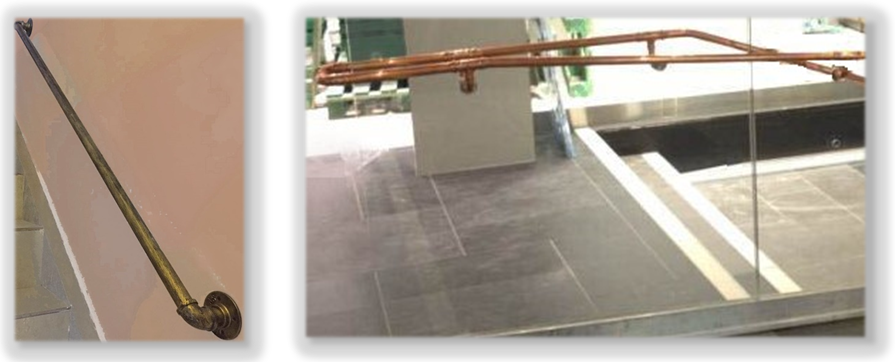

Copper coatings have microscopic porosities that prevent the development of bacteria and therefore it is recommended to use them on all surfaces where there is a high frequency of people such as: bus, subways, trains, airports, shopping centers, bar, schools, gyms, playgrounds, etc..

Copper coatings have microscopic porosities that prevent the development of bacteria and therefore it is recommended to use them on all surfaces where there is a high frequency of people such as: bus, subways, trains, airports, shopping centers, bar, schools, gyms, playgrounds, etc..

Since the antimicrobial properties are intrinsic to Copper and its alloys, the relative coatings must not undergo treatments subsequent to thermal spraying (don't ask, no paints, no other coatings) which would inhibit its properties.

The technique of electric arc spraying, whose thicknesses range from 50 until 1.000 micron, it also has an economic advantage, because copper deposits can be carried out on less valuable supports, such as iron, resins, wood, etc.., and replaces similar objects entirely in Copper (more expensive).