Vertic Zinc Wire Oy celebrate firsts 30 years of activity and strengthens its leadership in Northern Europe in the production of threads Zinc expanding the range of alloys Zn/Al 22 – Zn/Al 15 – Zn/Al 4 and Zn/Mn.

The main factors behind these successes are:

a) Use of Zinco SHG with the presence of Cd and Pb lower than 0,0016%, the purest on the market;

b) Production system in continuous vertical casting that, unlike traditional horizontal casting systems, allows you to have a starting rod diameter 8 mm, perfectly cylindrical, easy to extrude into the thinnest diameters up to 1,2 mm;

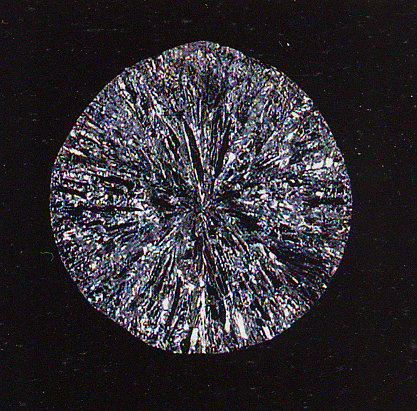

c) Clean threads and smooth surface with grain-oriented granular structure (isotropically) which have the same mechanical and thermal properties in all directions. The orientation of the grains, if not properly governed, negatively affects the physical characteristics, such as electrical and thermal conductivity, stiffness and toughness;

d) Degrees of hardness:

Vertic S for flame spraying systems

Vertic M for electric arc spraying systems

Vertic H for electric arc spraying systems with cables longer than 5 meters and for spraying Zn/Al alloys